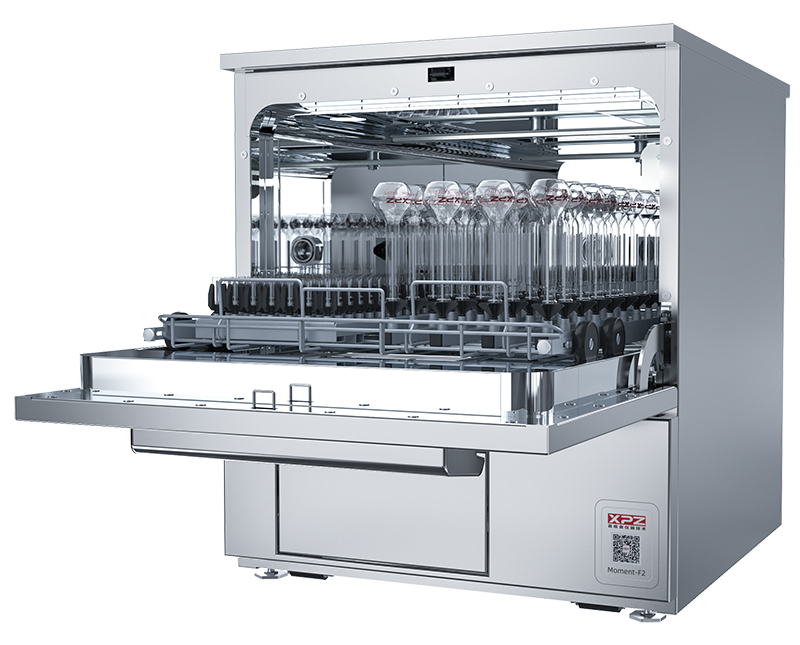

At 2 a.m. in the lab, Dr. Li stared wearily at a mountain of Erlenmeyer flasks—until a Made-in-China solution, the XPZ Moment-F2 Glassware Washer, transformed his daily grind. What used to be a 2-hour manual chore became a story of reclaimed time and renewed purpose.

—

### From “Glassware Janitor” to Scientist

The old way was a test of endurance:

- Time sink: 200 flasks required 2 people for 2 hours; stubborn grease meant overnight soaking.

- Breakage anxiety: 15% annual loss rate from student mishandling—each shattered graduated cylinder a blow to the lab budget.

- Unseen risks: “Visually clean” beakers still showed organic residues under UV tests.

The Moment-F2 revolution:

- 40-minute cycles clean + dry 80 pieces per load, saving 3 hours daily.

- Hands-off safety: Electronic locks prevent mid-cycle openings, eliminating chemical splash risks.

- AI efficiency: Auto-detects rack numbers, slashing water use by 70%.

### The Hidden “Soft Benefits”

1. Teaching tool:

- Color-coded racks cut student errors from 23% to 2%.

- Real-time water/electricity displays serve as live demos for *Lab Sustainability* courses.

2. Space wizardry:

- Its compact design frees 0.3㎡ bench space; wheels enable cross-lab sharing.

- One university created a “washer shift schedule” for 5 labs sharing 1 unit.

3. Glassware longevity:

- Non-abrasive coated racks + gentle spray triple lifespans, shrinking annual glassware budgets by 40%.

—

### Epilogue: When Science Stops Washing Dishes

Freed from scrubbing, researchers now invest those hours where they belong—in discovery. Perhaps this is technology’s quietest revolution: not just doing more, but *being* more.

Post time: Jun-24-2025