202L Automatic Laboratory Glassware Washing Machine for Cleaning Measuring Bottles, Volumetric Flasks and Other Glass Bottles with in-Situ Drying Function

Scope of application

Automatic washing machine, used in food, agriculture, pharmaceutical, forestry, environment, agricultural product testing, laboratory animals and other related fields to provide glassware cleaning solutions. Used for cleaning and drying Erlenmeyer flasks, flasks, volumetric flasks, pipettes, injection vials, petri dishes, etc.

Product Description Aurora-F2 laboratory glassware washer can be installed under the laboratory table-board or separately. It can be connected with tap water & pure water. The standard process is to use tap water & detergent to do mainly wash, then use pure water rinsing. It will bring you a convenient and fast cleaning effect, if you have drying requirements for cleaned utensils, please choose Aurora-F2.

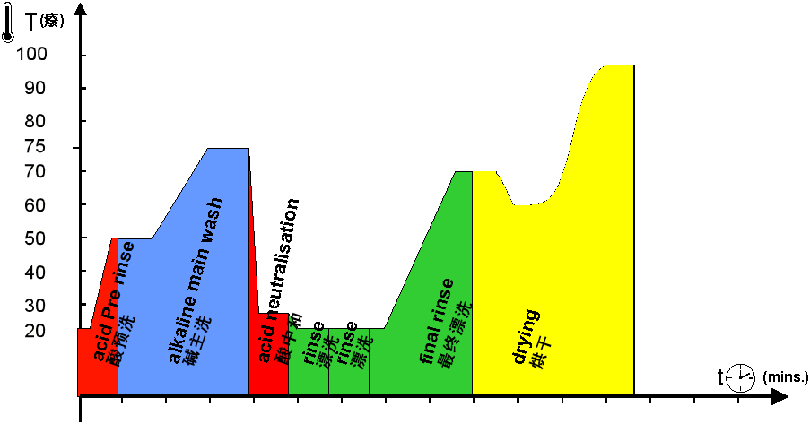

Characteristic: 1. It can be standardized for cleaning to ensure uniform cleaning results and reduce uncertainties in human operation. 2. It is easy to verify and save records for traceability management. 3. Reducing staff risk and avoid injury or infection during manual cleaning. 4. Cleaning, disinfection, drying and automatic completion, reducing equipment and labor input, so that saving costs ——-Normal washing procedure Pre-washing → washing with Alkaline detergent under 80°C → rinse with Acid detergent →rinse with tap water → rinse with pure water→rinse with pure water under 75°C→drying

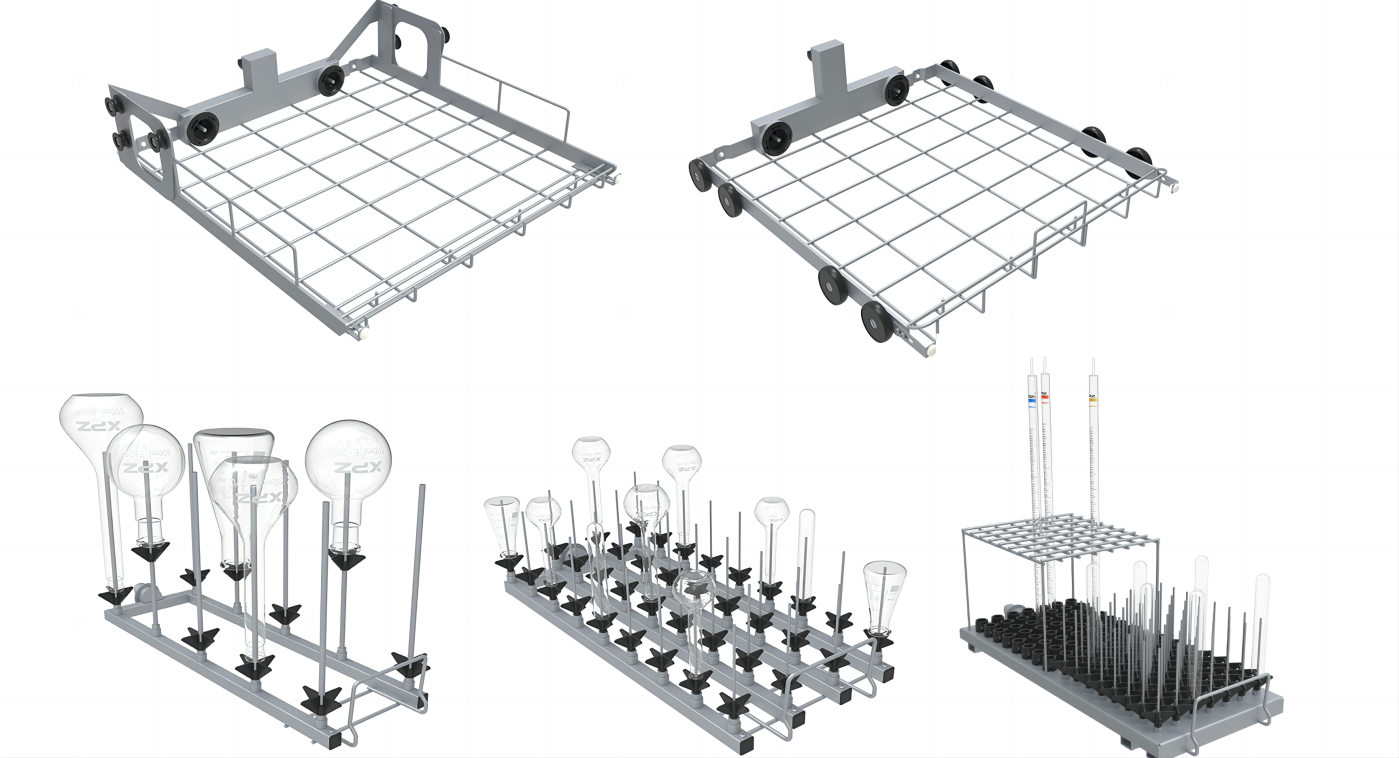

Technical innovation: Modular basket design  It is divided into upper and lower cleaning baskets. Each layer of basket is divided into two (left and right )modules. The module is arranged with automatic closing mechanical valve device. It can also be placed on any layer without changing the basket structure.

It is divided into upper and lower cleaning baskets. Each layer of basket is divided into two (left and right )modules. The module is arranged with automatic closing mechanical valve device. It can also be placed on any layer without changing the basket structure.

Specification

| Dimension (H*W*D) | 990*930*750mm |

| Number of cleaning layers | 3 layers |

| Chamber volume | 202L |

| Circulation pump flow rate | 0-600L/min adjustabie |

| Electricity | 280V/380V |

| Heating Power | 4kw/9kw |

| Basket identification system | Standard |

| Installation method | Freestading |

| Drying way | Hot air drying |

Operation management 1.Wash Start delay function: the instrument comes with appointment time start & timer start function to improve the customer’s work efficiency 2. OLED module color display, self-illumination, high contrast, no viewing angle limitation 3. level password management, which can meet the use of different management rights 4. Equipment fault self-diagnosis and sound, text prompts 5. Cleaning data automatic storage function (optional) 6.USB cleaning data export function (optional) 7. Micro printer data printing function (optional)

High cleanliness 1. Importedhigh-efficiency circulating pump in Sweden, the cleaning pressure is stable and reliable; 2. According to the principle of fluid mechanics, the cleaning position is designed to ensure the cleanliness of each item; 3. Optimized design of the rotary spray arm of the flat-mouth nozzle to ensure that the spray is 360° without dead angle coverage; 4. Wash the side of the column obliquely to ensure that the inner wall of the vessel is 360° cleaned; 5. Height-adjustable bracket to ensure effective cleaning of different sizes of vessels; 6. Double water temperature control to ensure the entire cleaning water temperature; 7. The detergent can be set and automatically added;

company file

Hangzhou Xipingzhe Biological Technology Co., Ltd

XPZ is a leading manufacture of laboratory glassware washer,located in hangzhou city,zhejiang province,china.XPZ specializes in research,production and trade the automatic glassware washer which is applied to Bio-pharma,Medical health,Quality inspection environment ,food monitoring,and petrochemical field. XPZ is committed to help solve all kinds of cleaning problems.We are the main supplier to Chinese inspection authorities and chemical enterprises.Meanwhile ,XPZ brand has been spread to many other countries,like india ,UK,Russia,South Korea,Uganda,the philippinese etc.,XPZ provides integrated solutions based on customized demand,including product selection ,installation and operate training etc. We will gather more enterprise advantage to provide innovtive products with high quality and excellent service ,to keep our long-term friendship.

Certification:

FAQ

Q1: Why Choose XPZ ?

We are the main supplier to chinese inspection authorities and chemical enterprises.

Our brand has been spread to many other countries,such as India,UK,Russia,Africa and Europe.

We provide integrated solutions based on customized demand,including product selection,installation and operate training.

Q2:What’s kind of shipment can customer choose?

Usually ship by sea, by air.

We try our best to meet the transportation requirements of customers.

Q3:How to ensure the product quality and after-sales service?

We have CE, ISO quality certificate and etc.

We have the excellent after-sales service and after sales engineer.

Our products have a warranty period.

Q4:Can we visit your factory online?

We are very supportive.

Q5:What kind of payment can customer choose?

T/T,L/C and etc.