The laboratory uses a large number of utensils made of glass, ceramics and other materials for sampling, purification, pretreatment, analysis, storage and other work. It can be seen that cleaning and drying utensils is very important, and cleaning and drying utensils must ensure that the next use is not affected by the previous use. Different laboratories have different requirements for the cleaning and drying of laboratory utensils. The cleaning process must ensure that the utensils are not affected by the previous use when they are used next time. In view of the different requirements for utensil cleaning in different laboratories, in order to meet the specific requirements of the laboratory , in determining the type of laboratory bottle washer, accessories, cleaning agents.

The cleaning agent used in the laboratory cleaning machine is specially used to clean the surface residue of laboratory glassware. Its purpose is not to neutralize the residue, but to peel off and replace the residue to adhere to the surface of the vessel. Because alkali is insoluble in water, it is necessary to It is neutralized with acid, and then discharged together with the waste liquid to achieve the purpose of removing experimental residues. The cleaning process is standardized and cleaner than traditional manual work.

The above shows that the Glassware Washing Machine has quick functions such as automatic cleaning, disinfection and drying. The operation process is mainly composed of three systems:

1. Conductivity online monitoring system

During the cleaning process, even very small residues in pure water can seriously affect the cleaning results. The Laboratory Washer is set with a system alarm function. If the conductivity in the last cleaning session exceeds the customer’s set value, the device will automatically add washing. The new maintenance-free online conductivity monitoring system provided by the bottle washer frees you from additional costs for maintenance and calibration. This system is integrated in the water circulation path, without direct contact with the water system, and the accuracy is extremely high.

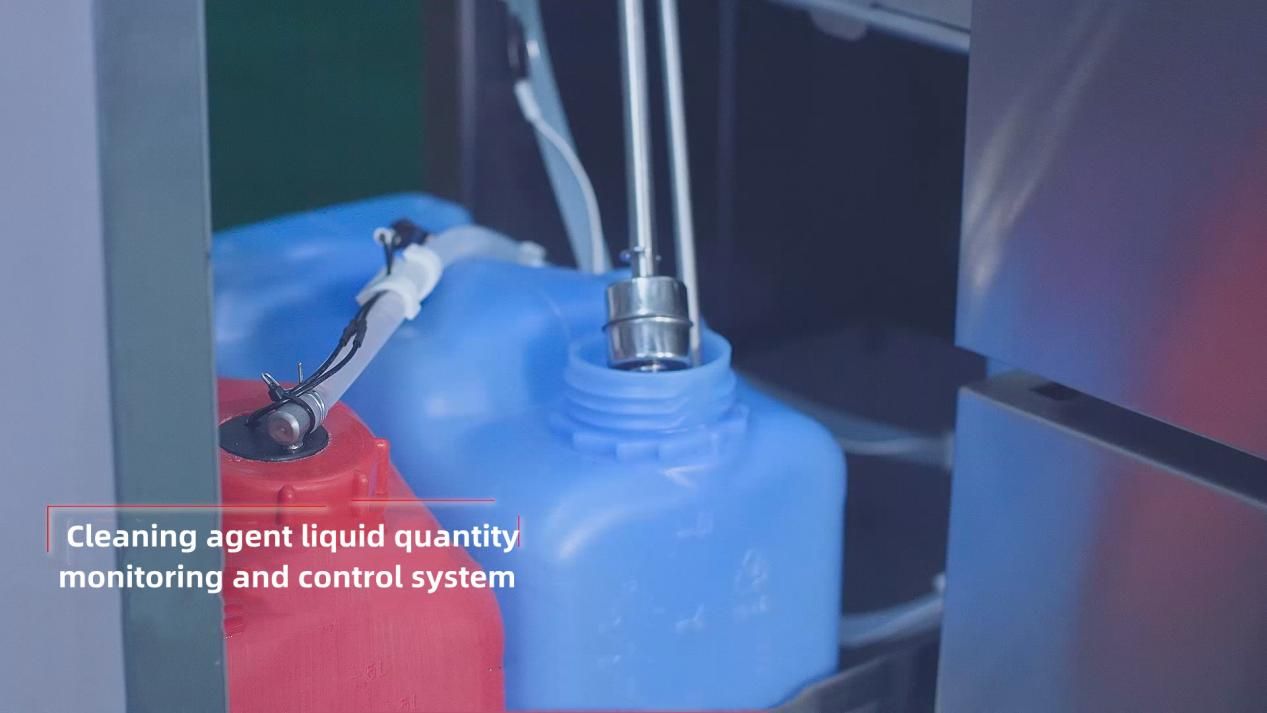

2. Cleaning agent liquid volume monitoring and control system

The cleaning agent liquid volume monitoring and control system of the Glassware Washer increases the safety of the system. When adding cleaning chemicals, the system can shield the effects of liquid viscosity and ambient temperature on liquid flow characteristics, allowing for more precise liquid distribution. The simple flow meter control method used in the past is affected by environmental factors. The new technology of the Lab Automatic Glassware Washer has higher accuracy and safety.

3. Spray arm flow rate sensing control system

With high-pressure spray cleaning function, that is, the spray arm flow rate sensing control system, the Glass Bottle Washing Machine can automatically identify the loaded basket system and accurately control the speed of the spray arm in the cleaning cavity. If the loading is wrong, the Laboratory Glass Washer Machine detects the error at the beginning of the program and suspends work. During the cleaning process, the Automatic Glassware Washer will detect the rotation speed of the spray arm to ensure that the rotation speed is within the set range, so as to achieve the best cleaning effect. If the speed of the spray arm is not up to standard, it indicates that there may be excessive foam.

The Automatic Glass Bottle Washer can process glassware in batches, which greatly improves the cleaning efficiency and reduces the labor intensity of operators. So that researchers have more valuable time to deal with other important work.

Post time: Apr-09-2022