At present, the domestic laboratories mainly use manual cleaning, for laboratory staff, the labor intensity is large, the risk of occupational infection is high, and for the cleaning results, the cleaning efficiency is low, the cleanliness cannot be guaranteed, and the repeatability is poor.

Through balancing time, temperature, cleaning agent distribution, mechanical

and inlet water quality, and with the help of the chemical force of professional cleaning agents, the Lab Washer can clean the glassware in a short period of time, which greatly improves the experimental efficiency, reduces the labor intensity and infection risk of the experimental personnel, and brings you a new working experience.

It takes more than 2 hours for laboratory manual cleaning of 460pcs vials, while it takes only 45 minutes to clean 460pcs vials with a Lab Dishwasher. While improving work efficiency, it also saves time and cost.

Laboratory bottle washer working principle:

The main principle of the lab glassware washer is to heat the water and add a special cleaning agent into the professional basket frame pipe through the circulating pump to wash the inner surface of the bottles. At the same time, there are also upper and lower spray arms in the cleaning chamber, which can clean the surrounding surfaces of the utensils.

For different shape of glasswares, it can be placed on different support baskets to ensure better spraying method, spray pressure, spray angle and distance; For different industry applications, can set different cleaning procedures, including different cleaning steps, different cleaning agent composition and concentration, different cleaning water quality, different cleaning temperatures.

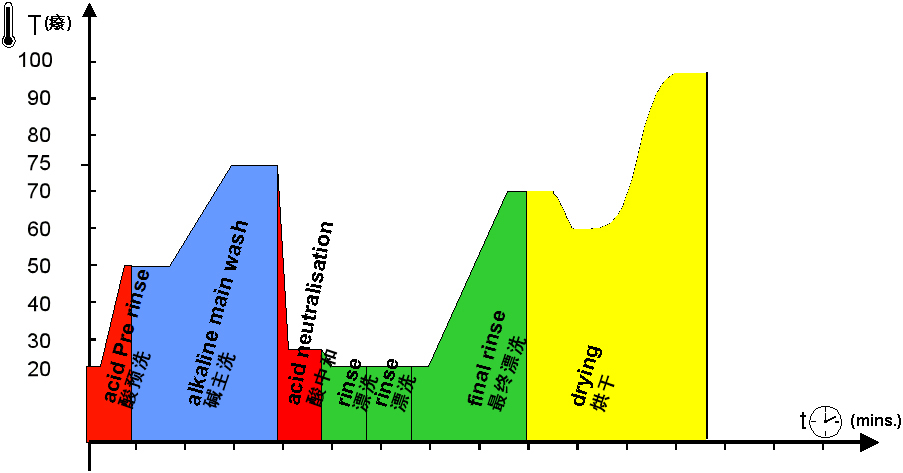

There are five main cleaning stages:

•The first stage is pre-cleaning , which rinses the glassware in a short time and roughly removes residues that are not strongly adhered;

•The second stage is mainly cleaning, this stage is longer, the internal temperature of the instrument gradually increases (can be controlled at 60-95 ° C), and with high-pressure washing, many stubborn residues attached to the inner wall will gradually fall off;

•The third stage is neutralization cleaning, this process uses the principle of acid-base neutralization to control the cleaning environment to neutrality;

•The fourth stage is rinsing, after the main cleaning work is completed, the instrument will spray the glassware to remove detergent and stains;

•The fifth stage is drying, after cleaning, the glassware can be dried for experimental use again.

Post time: Feb-18-2022