Recently, a pharmaceutical company was investigated and dealt with by relevant authorities due to potential safety hazards in the quality management system and compeled the pharmaceutical company to immediately suspend production for rectification, and the company’s original “drug GMP” certificate was also withdrawn.

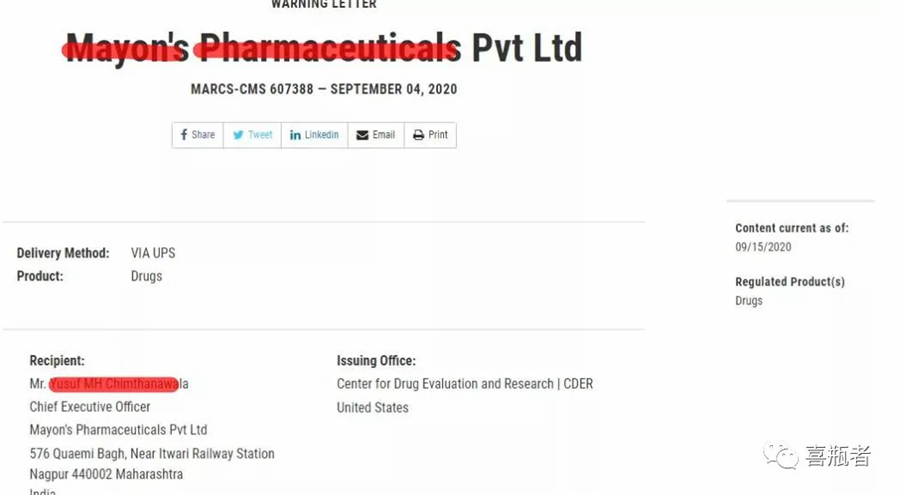

Coincidentally, in September 2020, the FDA (U.S. Food and Drug Administration) issued a warning letter against an antibacterial drug company in India.The letter seriously warned that the company did not strictly implement the standardized cleaning verification procedures when producing the latest drug, but focused on the formal elimination of bacteria, which would lead to the risk of other contamination of the cleaning effect and the unavailability of the quality of the manufactured drugs. Guaranteed. Therefore, it is confirmed that the FDA will not approve the drug to enter the consumer market in the United States until it is confirmed that the company can actually improve the related problems.

Looking at the above two cases, there is one thing in common that has to attract the attention of the industry, that is, the problem of the cleaning verification link has not been resolved smoothly, and it does not meet the official certification requirements. In other words: cleanliness is the key to determining drug safety, and it runs through the entire process of pharmacy.

In fact, with the implementation of the new version of GMP (Good Manufacturing Practice), higher requirements have been put forward for pharmaceutical companies in terms of pharmaceutical quality control, especially in the specific aspects of R&D, production, quality control, and transportation.

For a pharmaceutical company, GMP is a nationally enforced policy. Companies that fail to benchmark or maintain GMP within the prescribed time limit will be punished to varying degrees, including warnings and suspension of production. It is a very complicated process to make the quality of medicines meet the eligibility standard. Among them, cleanliness is one of the important indicators to measure whether pharmaceutical companies have stable production capacity.Many pharmaceutical companies are not approved to continue production after being inspected by relevant departments. The fundamental reason is precisely the key link-the cleaning utensils are not clean. In particular, laboratory utensils made of glass, plastic, etc. Cannot ensure the thorough cleaning of residual contaminants.

It is worth emphasizing that at present, many pharmaceutical companies focus only on disinfection and sterilization, but ignore another more important step-cleaning verification. This is obviously a wrong understanding. As you know that the important details of the cleaning verification must also include disinfection and sterilization and thorough cleaning of the pharmaceutical company’s laboratory. From a certain perspective, the latter is more important than the former. The reason is that the cleaning verification process usually covers the method development phase, the program preparation phase, the program implementation phase, and the verification status maintenance phase. These four stages are almost all carried out around the core content of GMP, which is how to “minimize the pollution and cross-contamination in the drug production process”. At each stage of the experimental verification link, it is also inseparable from the glassware washing standard as a prerequisite for obtaining accurate, effective and reliable results of detection and analysis.

It is not unattainable that the laboratories of relevant companies want to improve the cleaning problem of utensils and enhance the cleaning effect-it is enough to upgrade and replace the original manual cleaning method with an automatic cleaning system. For example, the introduction and use of a automatic glassware washer is one of the best solutions.

The automatic glassware washer adopts a spray cleaning method. The residues on the surface of the ware can be peeled off by the hot water and lotion to soak the residual substances, so that the ware can be clean and bright again. Utilizing the high-pressure water jet from the spray arm and the basket frame, the Lab Washer can pass the water flow directly through the washing internal area through the circulating washing pump to any corner of the washing target. When the water passes through the heater to form a high temperature and is used in the form of a water column, it can effectively wash away various pollution residues attached to the top of the removal vessel, thereby achieving the purpose of cleaning and drying. Not only that, the use of the automatic washing system for the Laboratory Washer has high cleaning efficiency (automatic glassware washer batch work, repeated cleaning process), low bottle breaking rate (adaptive adjustment to water flow pressure, internal temperature, etc.), and wide versatility ( It can accommodate test tubes, petri dishes, volumetric flasks, conical flasks, measuring cylinders, etc. of various sizes and shapes, and the whole process is intelligently operated, safe and reliable (pre-installed imported explosion-proof safe water inlet pipe, pressure and temperature resistance, not easy to knot Dirt, with anti-leak monitoring valve, the instrument will automatically close when the solenoid valve fails). In addition, the laboratory glassware washer can instantly present important data such as conductivity, TOC, lotion concentration, etc., which is convenient for relevant personnel to monitor and master the cleaning progress and connect the system to print and save it is very beneficial, providing convenience for later traceability .

Lab Washing Machine helps pharmaceutical companies to reduce the generation of cross-contamination, helps to ensure the improvement of each link of the pharmaceutical company’s cleaning verification, and also helps the pharmaceutical companies to improve the overall level of equipment application. It is in full compliance with the regulatory requirements set by GMP in various countries. It is worthy of reference and use by the majority of pharmaceutical companies.

Post time: Mar-15-2021