Fully automatic PTFE acid cleaner with super microwave function

Product Description:

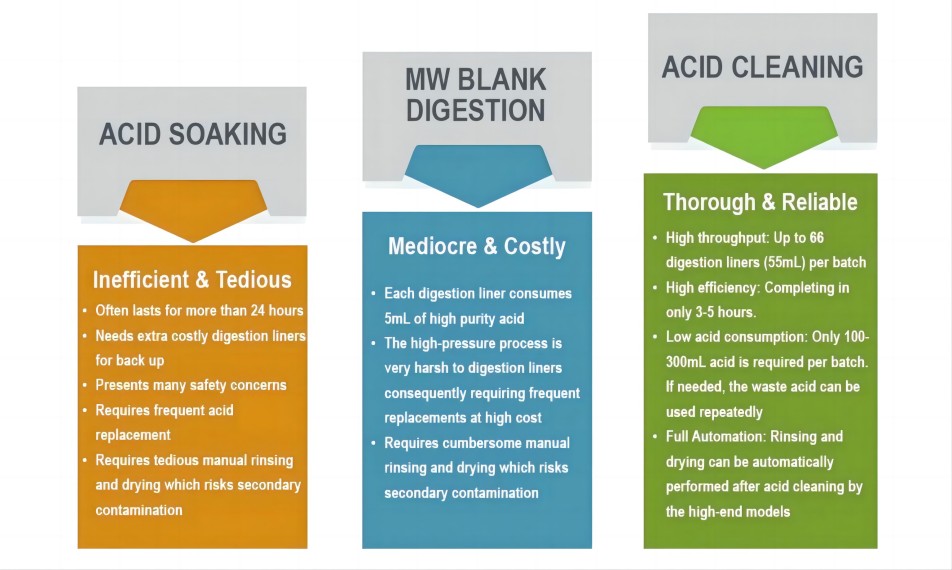

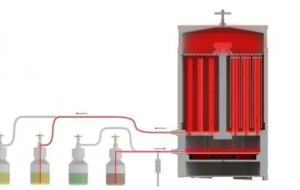

The acid cleaner is also known as Acid Steam Cleaning System or Trace Cleaning System. It uses acid vapor to clean the vessels in a sealed chamber. Through a built-in temperature-control heating system, all trace metal contaminants that are soluble in acid can be safely and efficiently removed by acid vapor. The used acid will then be drained from the chamber to prevent the extracted contaminants from being reintroduced to the cleaned vessels.

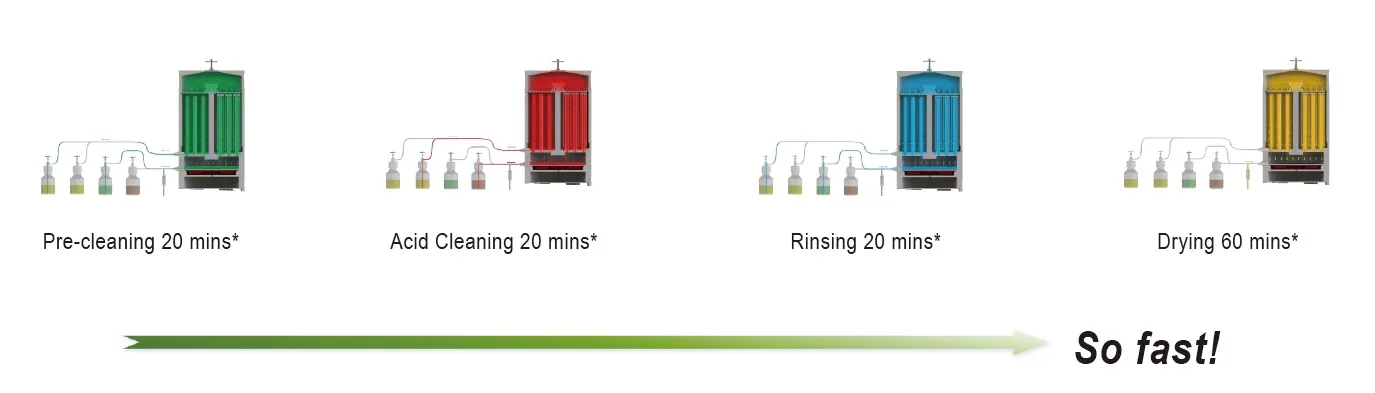

Acid cleaning:

Cleaning process:

Acid vapor cleaning:

Ultra-pure water rinsing:

Hot air drying:

Characteristic:

One-Way Vapor Technology(OWV)

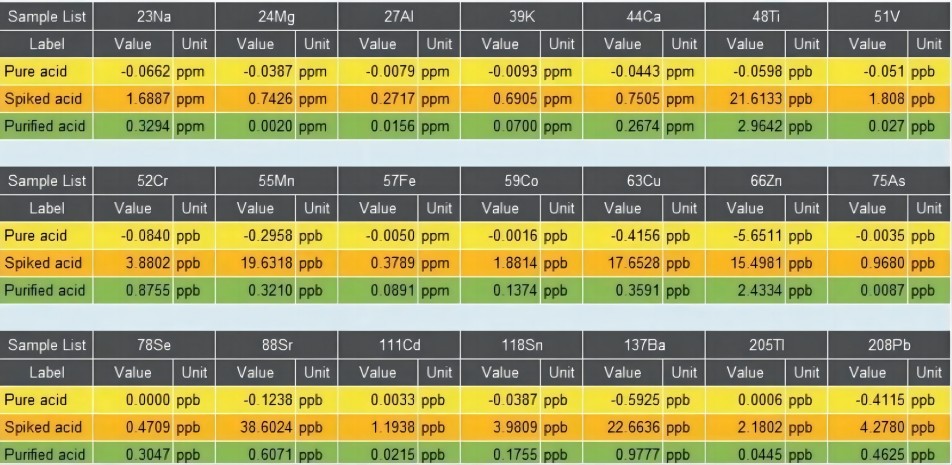

No secondary contamination from the waste acid

OWV ensures that the used acid is drained directly from the system so there is no reflux into the acid reservoir risking contamination. In traditional techniques, the waste acid will repeatedly reflux into the acid reservoir and evaporate. As a result, the waste acid constantly contaminates the pure acid. The resulting vapor becomes dirtier and the cleaning efficiency worsens. Consequently, even with trace metal grade pure acid only ppb-level cleaning can be achieved.

More durable, More Stablize

Real-time level monitoring

No inadequate cleaning or overflow

Automatic Acid Dilution

No chemical hazard

The dangerous concentrated acid can be automatically diluted to any desired concentration.Zero human contact with the acid.

Waste removal via vacuum

Leask proof

Non-contact removal of the hugh-temperature waste safely prevents damage to the pump Eliminates 1-2 hours awit for waste cooling.

Real-time pressure control

No overpressure or misoperation

The whole cleaning process is under negative pressure,there is no danger of high pressure! The inert pressure sensor automatically reduces the magnetron’s power once the pressure exceeds the preset range,and automatically restores the power after the pressure drops within the preset range,which prevents the genreation of hugh pressure and avoids acid vapor leaking.Before running,the system does a self-check for the seal.If the self-check fails,the cleaning will not be allowed,and the user will be reminded to check whether the bottle caps are closed,the cleaning chamber’s lid is tightened,and the pipe joints are eonnected,etc.

Multiple protections extend the life span

No overheating of magnetron

The cooling system is enhanced to significantly extend the life span of the magnetron.Both the magnetron and its power supply are equipped with a temperature protection switch to prevent over-heat.Besides those,a thermostat is interated with the magnetron.Once the magnetron is overheated, the power will b ecut off and will be restored automatically after the temperature drops to a safe range.

Multiple safety interlocks

Proven tcehnologies

Chole groove design widely used in the industry.The leakage amount is much lower than the nationa standard(<5mw/cm3@5cm).The protection system will be triggered and automatically turn off the microwave to avoid microwave laekage once the microwave signal cable is disconnected or one or two interlocking devices fail,etc.

Company file:

Exhibition

Hangzhou Xipingzhe Biological Technology Co., Ltd

XPZ is a leading manufacture of laboratory glassware washer,located in hangzhou city,zhejiang province,china.XPZ specializes in research,production and trade the automatic glassware washer which is applied to Bio-pharma,Medical health,Quality inspection environment ,food monitoring,and petrochemical field.

XPZ is committed to help solve all kinds of cleaning problems.We are the main supplier to Chinese inspection authorities and chemical enterprises,meanwhile XPZ brand has been spread to many other countries,like india ,UK,Russia,South Korea,Uganda,the philippinese etc.,XPZ provides integrated solutions based on customized demand,including product selection ,installation and operate training etc.

We will gather more enterprise advantage to provide innovtive products with high quality and excellent service ,to keep our long-term friendship.

Certifications

FAQ:

Q1: Why Choose XPZ ?

We are the main supplier to chinese inspection authorities and chemical enterprises.

Our brand has been spread to many other countries,such as India,UK,Russia,Africa and Europe.

We provide integrated solutions based on customized demand,including product selection,installation and operate training.

Q2:What’s kind of shipment can customer choose?

Usually ship by sea, by air.

We try our best to meet the transportation requirements of customers.

Q3:How to ensure the product quality and after-sales service?

We have CE, ISO quality certificate and etc.

We have the excellent after-sales service and after sales engineer.

Our products have a warranty period.

Q4:Can we visit your factory online?

We are very supportive.

Q5:What kind of payment can customer choose?

T/T,L/C and etc.