With the rise of laboratory labor costs and the integration with internationalization, the full-automatic laboratory glassware washer has been paid more and more attention by laboratory leaders. After this, many imported and domestic brands have sprung up, and the Lab Washing Machine has been popular by everyone. As a new thing in the field of laboratory equipment, automatic glassware washer seems simple, but it is actually complex. It is difficult to achieve cleanliness level, high efficiency, safety and stable operation. It involves the machining of the inner cavity of the shell, control program, heating control, reagent addition, various operating sensors, water quality control and other technologies. Compared with the drying oven, it involves cold and hot water, acid and alkali, heating, drying, fluid balance and so on. It is much more complex than the drying oven. It is difficult to do a good job in the drying oven, so it is more difficult to produce glassware washer.

So what are the system technical characteristics of the lab glassware washer designed through experience and practical application?

1.Spray

The centralized upper and lower forest spraying device is configured, and the nozzles are asymmetrically distributed to improve the spraying coverage. Eliminate the shadow effect and greatly improve the cleaning effect and speed.

2.Control procedure

There are 25 standard cleaning programs and 100 custom programs that can meet most cleaning requirements. All program parameters can be controlled, including time, temperature, concentration of detergent / neutralizer and drying. This program is also applicable to various challenging cleaning tasks.

3.Water inlet flowmeter

The water inflow flowmeter can accurately control the water inflow, so that the set water volume can be used in each step. Accurate water inflow control can also ensure the proper ratio between water and detergent.

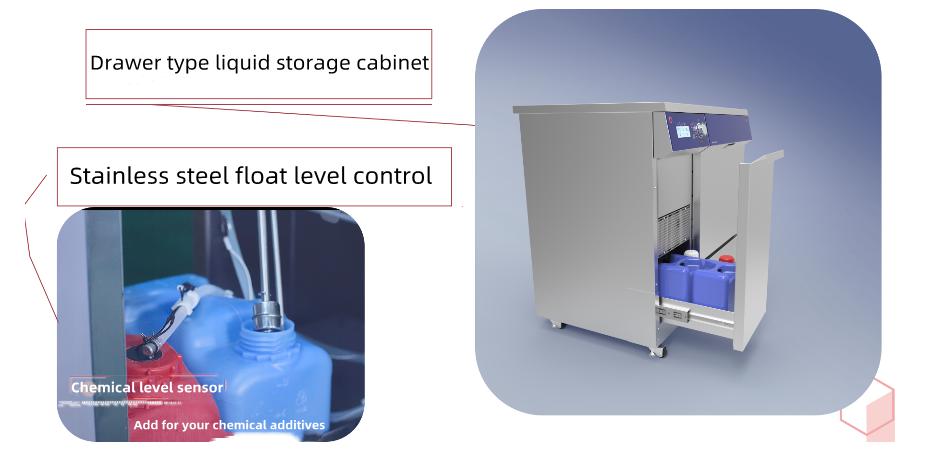

4.Distribution system

Two dispensing pumps can automatically and accurately dispense detergent and neutralizer. On the base of the cleaning and disinfection machine are two 5-liter storage boxes, which provide a convenient storage scheme. Each peristaltic pump is equipped with flow control to ensure that water and detergent are mixed in the correct proportion.

5.Circulatory system

The circulating pump with a flow rate of 800 liters per minute provides a strong cleaning capacity. The rotating spray washing arm installed in the washing room can clean the surface of glassware, the spray washing arm on the lower layer can also clean the internal surface of the glassware, as long as the glassware has a large opening and is placed on the certain layer. In the washing chamber, a water outlet that can connect multiple injection systems is provided. This connection port can also provide water to the basic washing support on the upper layer.

Fully automated Laboratory Washer and disinfection is a modern washing method, which loads glassware of different shapes into a closed cleaning space through different baskets, and automatically completes the cleaning steps of pre-washing, cleaning, neutralization washing, rinsing and drying by using a software programming technology, water treatment technology, chemical reagent formula, temperature sensing technology, hot air drying technology. It greatly reduces the infection risk and labor intensity of operators, saves manpower and time, and reduces biological pollution to the environment.

To sum up, the cleaning and disinfection process of the bottle washing machine is fully enclosed, and not in contact with people, and the thermal disinfection effect is achieved by increasing the temperature during washing. In the long run, the automatic cleaning of utensils by machines is the development trend of modern laboratories.

Post time: Jul-07-2022