Laboratory Washer Undercounter FlaskScrubber Glassware Washer with Viewing Window and Light

Undercounter Flask Scrubber Glassware Washer

Scope of application

Automatic washing machine, used in food, agriculture, pharmaceutical, forestry, environment, agricultural product testing, laboratory animals and other related fields to provide glassware cleaning solutions. Used for cleaning and drying Erlenmeyer flasks, flasks, volumetric flasks, pipettes, injection vials, petri dishes, etc.

Automatic cleaning meaning

1. Can be standardized for cleaning to ensure uniform cleaning results and reduce uncertainties in human operation.

2. Easy to verify and save records for easy traceability management.

3. Reduce staff risk and avoid injury or infection during manual cleaning.

4. Cleaning, disinfection and automatic completion, reducing equipment and labor input, saving costs

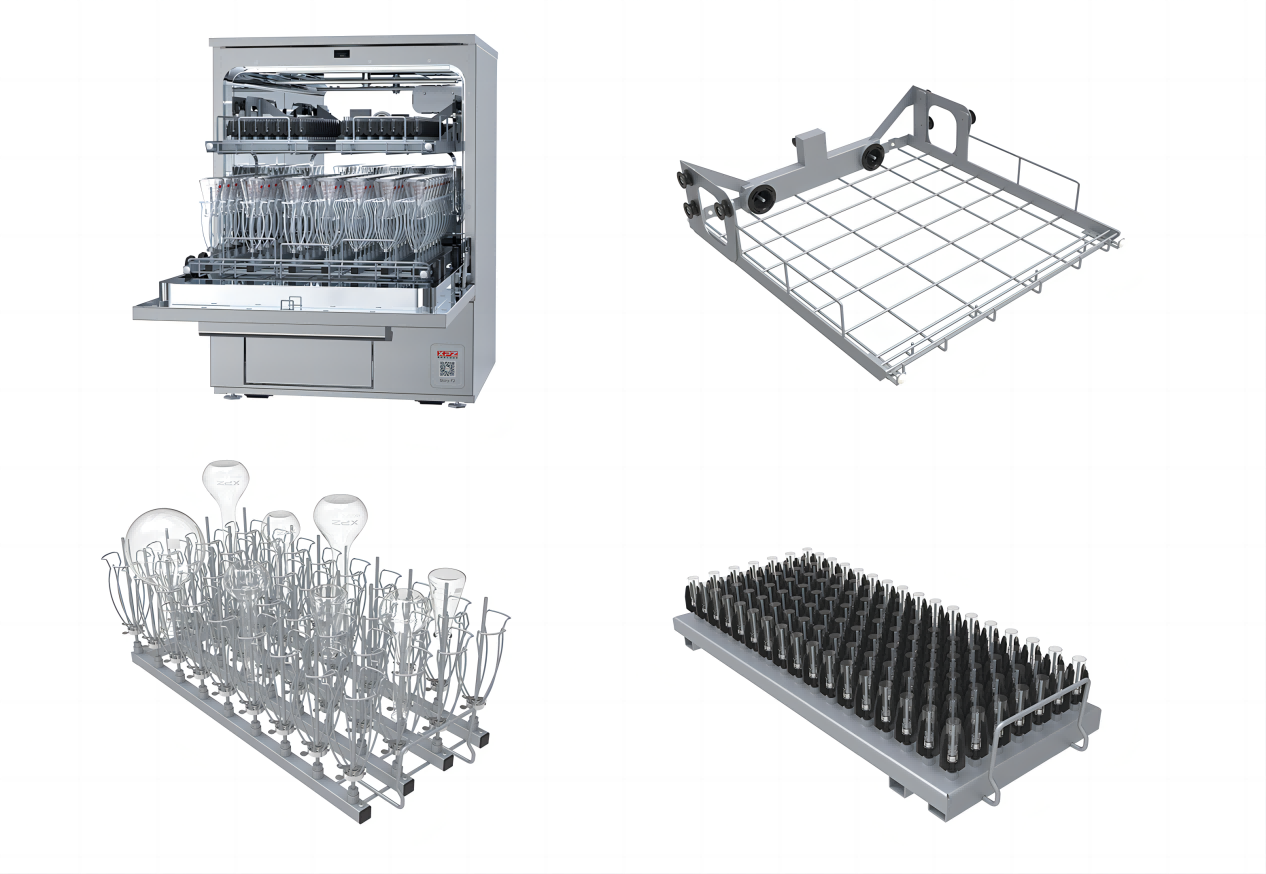

Technical Innovation ——Modular cleaning baskets

Independent cleaning module, 4 cleaning modules can be placed in each cleaning, such as Injection module for Volumetric flask , Injection module for conical flask

, Injection module for Sampling tube etc. ,Injection module for Pipettes.

, chicken heart bottle cleaning module, round bottom flask cleaning module, Liquid funnel cleaning module, pipette cleaning module, etc., each time you wash different utensils, you can choose different cleaning modules for free combination to achieve comprehensive free combination cleaning

Importance:

1; free independent module

2; The combination is as big as: AAAA / BBBB / CCCC / AABB / AAEE / ABEG, etc.

3; The number of cleaning is more big, modular cleaning uses all the cleaning space.

4; Proof of cleaning ability: injection vials can clean more than 468 positions, 144 positions for 5-50ml volumetric flasks, and 200 positions for pipettes

High cleanliness

1. Imported high-efficiency circulating pump in Sweden, the cleaning pressure is stable and reliable;

2. According to the principle of fluid mechanics, the cleaning position is designed to ensure the cleanliness of each item;

3. Optimized design of the rotary spray arm of the flat-mouth nozzle to ensure that the spray is 360° without dead angle coverage;

4. Wash the side of the column obliquely to ensure that the inner wall of the vessel is 360° cleaned;

5. Height-adjustable bracket to ensure effective cleaning of different sizes of vessels;

6. Double water temperature control to ensure the entire cleaning water temperature;

7. The detergent can be set and automatically added;

Operation management

1.Wash Start delay function: The instrument comes with appointment time start & timer start function to improve the customer’s work efficiency;

2. OLED module color display, self-illumination, high contrast, no viewing angle limitation

3. level password management, which can meet the use of different management rights;

4. Equipment fault self-diagnosis and sound, text prompts;

5. Cleaning data automatic storage function (optional);

6.USB cleaning data export function (optional);

7. Micro printer data printing function (optional)

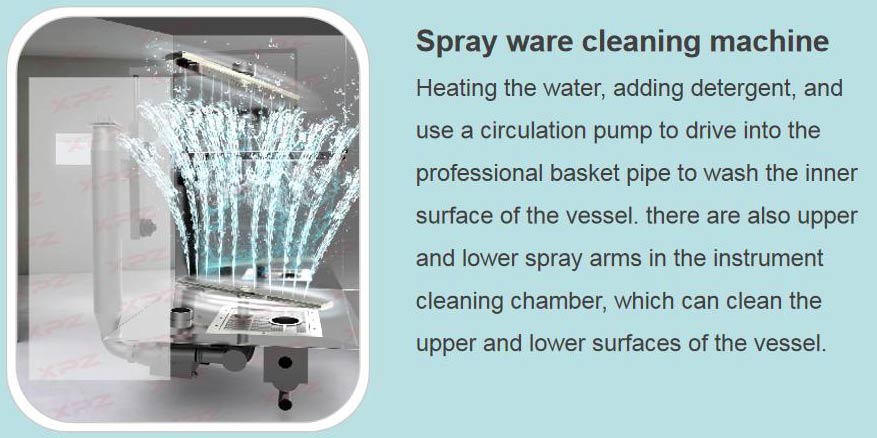

Automatic glassware washer—principle

Heating the water, adding detergent, and use a circulation pump to drive into the professional basket pipe to wash the inner surface of the vessel. there are also upper and lower spray arms in the instrument cleaning chamber, which can clean the upper and lower surfaces of the vessel.

Product Description:

Glory-2 / F2 laboratory glassware washer,can be installed under the laboratory table-board or separately. It can be connected with tap water & pure water. The standard process is to use tap water & detergent to do mainly wash, then use Pure water rinsing. It will bring you a convenient and fast cleaning effect, when you have drying requirements for cleaned utensils, please choose Glory-F2.

Specification:

| Basic Data | Functional Parameter | ||||

| Model | Glory-2 | Glory-F2 | Model | Glory-2 | Glory-F2 |

| Power Supply | 220V/380V | 220V/380V | ITL automatic door | Yes | Yes |

| Material | Inner Chamber 316L/Shell 304 | Inner Chamber 316L/Shell 304 | ICA Module | Yes | Yes |

| Total Power | 5KW/10KW | 8KW/13KW | Peristaltic Pump | 2 | 2 |

| Heating Power | 4KW/9KW | 4KW/9KW | Condensing Unit | Yes | Yes |

| Drying Power | N/A | 2KW | Custom Program | Yes | Yes |

| Washing Temp. | 50-93℃ | 50-93℃ | OLED Screen | Yes | Yes |

| Washing Chamber Volume | 170L | 170L | RS232 Printing Interface | Yes | Yes |

| Cleaning Procedures | 35 | 35 | Conductivity Monitoring | Optional | Optional |

| The Layer Number of Cleaning | 2(Petri dish 3 layers) | 2(Petri dish 3 layers) | Internet of Things | Optional | Optional |

| Pump Washing Rate | 500L/min | 500L/min | Dimension(H*W*D)mm | 830×612×750mm | 830×612×750mm |

| Weight | 110KG | 110KG | Inner cavity size (H*W*D)mm | 557*540*550mm | 557*540*550mm |