The lab glassware washer is designed for cleaning various glassware.It has a large cleaning space.The base is equipped with universal wheels,which is easy to move.The overall is small therefore can used in small space.At the same time,drying and condensation system can be selected according to customer needs.After cleaning the utensils can be dried by themselves,saving users time and labor costs for cleaning operations.And customized cleaning baskets can be selected according to the actual situation,from small flasks to large measuring cylinders, can ensure clean cleaning, and can be equipped with softened or pure water supply components according to your needs.

The cleaning cabin of the XPZ laboratory glassware washer is a one-time molding process, and is made of 316 sanitary stainless steel.Consequently beautiful appearance, good sealing, anti-corrosion, no leakage, improve cleaning efficiency, comparable to imported cleaning machine products

The functional characteristics of the laboratory washing machine:

1.The cooler with large capacity can reasonably avoid the potential safety hazard caused by the discharge of sewage vapor in the laboratory.

2.The high efficiency drying system consists of air heating,large capacity coolers, filtration units and high-efficiency centrifugal fan can quickly and cleanly air-dry the container during the whole process of heating,steam blowing,sewage and waste gas discharge in circulatory system.

3.The two-point anti-theft locking mechanism makes the door seal more reliable and avoids the outflow of water and steam.

4.The circulating water pump is maintained at high temperature to avoid abnormal high temperature damage to the circulating water pump.

5.The water circulatory system pipeline is equipped with mesh filter system to prevent the slag from entering the circulation during the whole cleaning process, thereby maintaining the internal components.

6.The fully automatic suction hybrid electronic device safety door lock avoids the side door are opened during the cleaning and drying process to harm personal safety.

7.Contains an emergency power switch to ensure that the power is turned off in times of crisis.

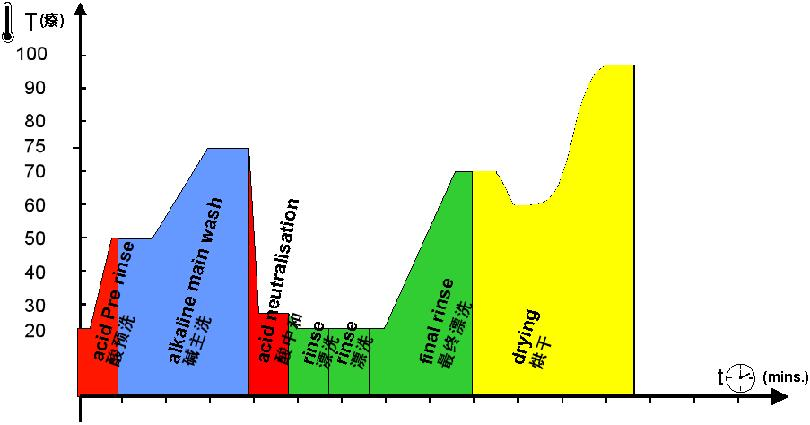

Lab glassware washer cleaning process:

The cleaning water solution enters the spouting arm and the spouting pipe under the pressurizing driver of the circulating water pump, and the cooling circulating water drives the spouting arm after pressurization to rotate to clean the utensils. It is placed in the cleaning chamber, and automated technical equipment is used to clean the utensils. In general, auxiliary cleaning agents must be added to carry out cleaning, and processes such as pre-washing – main washing – neutralization – rinsing and drying can be carried out. The whole process of cleaning can be recorded, traced back, and the cleaning process can be verified.

1.Pre-wash:remove some dirt and large-scale air pollutants that are very easy to remove.

2.Main washing:Add detergent to make it easier to clean up hard-to-remove dirt.

3.Neutralization:Add other detergent for acid-base neutralization to ensure that the pH value is in the normal range at the end of cleaning.

4.Rinsing:Using water or pure water to remove detergent residue.

5.Drying: Dry or air dry.

application:

Effective cleaning, disinfection and drying of laboratory glass, ceramics, metal, plastic, rubber and other materials, various shapes and sizes of utensils, including petri dishes, glass slides, test tubes, Erlenmeyer flasks, conical flasks, beakers, measuring cylinders, Jars, leaks, and holding bottles, etc.

The laboratory bottle washer is suitable for large-scale cleaning of glassware in scientific research centers, schools, and medical units, especially for cleaning large-scale utensils that cannot be cleaned by ordinary cleaning machines. Acidic, alkaline cleaning solution or neutralizing solution can be added to the utensils used for different experiments. The cleaning, drying and disinfection operations are completed at one time through the cleaning procedure, without the need to purchase additional drying boxes and disinfection cabinets, saving manpower and equipment investment.

Post time: Nov-17-2022